Material evaluation

Accelerated Evaluation of Anticorrosion Coatings regarding Durability against Under-Film Corrosion

Overview

Osaka Gas is working on the development of a test method for evaluating, in a short period of time, anticorrosion coatings as to their long-term durability against under-film corrosion.1

1. Corrosion that occurs at the interface between paint (coating film) and steel in painted structures

Background

Many outdoor steel structures are coated with an anticorrosion paint, but the coating film deteriorates with long-term use, and corrosion may occur under the coating film. Areas where corrosion has occurred are repaired (repainted). However, in the areas where it is difficult to completely remove rust due to corrosion, corrosion under the paint film may recur in a period shorter than the expected service life. An exposure test is generally performed to evaluate the durability of coatings against such under-film corrosion, but it takes a long time. Therefore, a test method for accelerated evaluation in a short period of time is desired. Osaka Gas is working on developing such a method.

Details

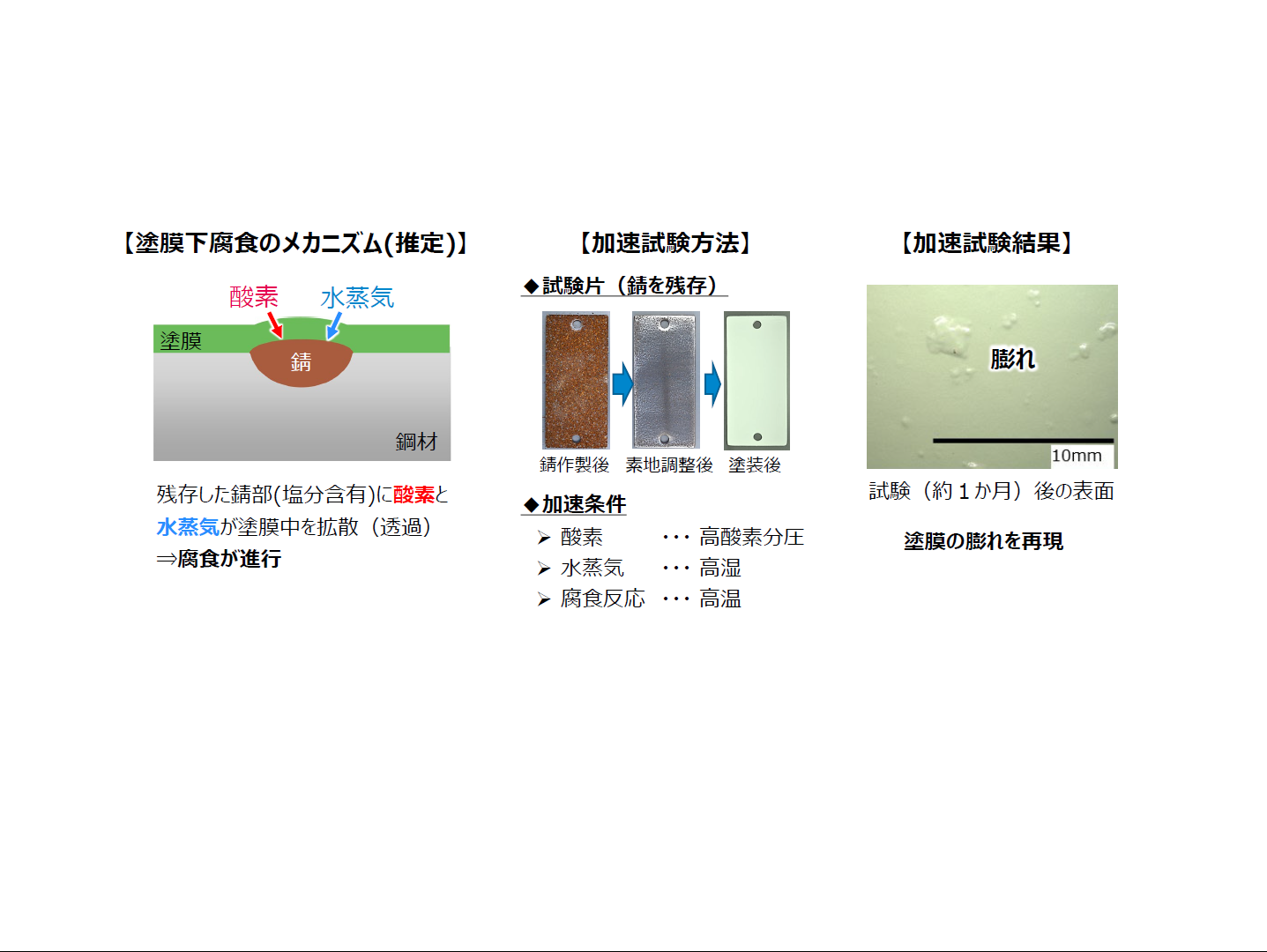

To reproduce under-film corrosion under close-to-actual conditions in a short period of time, we focused on its mechanism and devised a test, in which the test pieces with rust remaining are held under high oxygen partial pressure, high temperatures and high humidity. The test results showed that blistering caused by under-film corrosion, which would normally take several years of exposure testing, could be reproduced in only about one month. We believe that this test method will enable us to evaluate the durability of repainted parts of corroded steel structures in a short period of time. We are conducting further studies on test pieces preparing method and conditions to establish a test method for comparing the durability of paints and estimating their service life.

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group