Air conditioning systems, kitchen appliances

A Study on Required Ventilation Rates for Commercial Kitchens

Purpose

The required ventilation rate for a commercial kitchen with gas appliances is stipulated to be at least the legal ventilation rate determined according to the combustion exhaust rate. In contrast, commercial kitchens with electric appliances in some cases are designed at less than half the legal ventilation rate for those with gas appliances because there are no applicable legal regulations. This is based on various reports stating that electromagnetic cookers require a ventilation rate less than that required by gas appliances for clearing out cooking exhaust, such as oily smoke, as measured under a no-airflow condition, disregarding irregular airflows in the kitchen. However, in an actual commercial kitchen, irregular airflows occur due to air blowing from air conditioners, windows, entrances, and the like and due to the movement of the kitchen staff. Therefore, we studied the capturing of cooking contaminants by using gas and electromagnetic cooktops and fryers with comparable capacity, focusing on the effects of airflows likely to be caused by air conditioning and the movement of kitchen staff. The research was conducted jointly with Osaka University.

Experimental Method

Under the condition illustrated in Fig. 1, the cooking appliances described in Table 1 were used. To measure cooking contaminants, a tracer gas (SF6) was used. The cooking contaminants capturing rate was calculated as the ratio of the concentration determined with the enclosure removed to the concentration determined with the enclosure provided all around the exhaust hood, as shown in Fig. 1. Irregular airflows due to disturbances were produced as follows.

- 1. Disturbances such as from air conditioning were produced by a constant-velocity lateral airflow generator installed to the left of the cooking appliances. (Fig. 1)

- 2. Disturbances due to kitchen staff were produced by moving a mannequin in front of the cooking appliances at a constant speed (3.6 km/h). (Fig. 2)

| Cooktop | Fryer | ||

|---|---|---|---|

| Approach | Identical capacity to heat the pot | Identical oil tank area | |

| Test Conditions | Water continuously boiled in a 36 cm pot for electromagnetic cooker | Standby (oil temperature: 170°–185°) When cooking potatoes (oil temperature: 170°–185°) |

|

| gas | Input | 14.5kW (12,500kcal/h)×2 | 11.6kW (10,500kcal/h)×2 |

| electromagnetic | Input | 5KW ×2 | 5KW ×2 |

| Ventilation rate | 540〜1620m3/h | 440〜1320m3/h | |

| Exhaust hood dimensions | W1200×D750×H640mm Bottom of hood at 1,860 mm from floor |

||

【Test Conditions】

Test Results

1. Effects of Airflows in the Kitchen

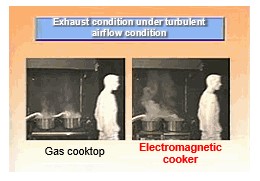

Smoke from a smoke machine was used to monitor cooking exhaust flows.

![[無風時の調理排気の流れ] ガスレンジ 電磁調理器](/en/rd/topic/__icsFiles/afieldfile/2023/12/01/02_6.jpg)

Under no airflow condition, exhaust gases from the electromagnetic cooker could be captured at ventilation rate less than that for the gas cooker.

![[横風がある時の排気捕集率状況] ガスレンジ 電磁調理器](/en/rd/topic/__icsFiles/afieldfile/2023/12/01/03_5.jpg)

The test results show that even with a weak lateral airflow, the exhaust gases from the electromagnetic cooker are easily diverted and overflow from the exhaust hood.

2. Capturing Rate Measurement Results

![[レンジの場合の調理排気捕集率]](/en/rd/topic/__icsFiles/afieldfile/2023/11/17/04_5.jpg)

3. Effects of Kitchen Staff’s Movements

A mannequin was moved in front of the cooktop to represent the movements of a cook in a commercial kitchen. Under this setup, how the cooking exhaust gases are captured was investigated. [Passing speed of mannequin of 1.0 m/s (3.6 km/h), 300 mm away from the front of the cooktop)

Conclusion: From the above results, given an environment, such as an actual kitchen, in which irregular airflows occur, cooking using an electromagnetic appliance requires the same or a higher ventilation rate as compared with a gas-fired appliance of the same cooking capacity. Otherwise, cooking exhaust gases such as oil smoke will overflow from the exhaust hood and a higher level of stagnant oil smoke occurs in the kitchen.

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group