Industrial furnaces, burners

Recuperative Burner

Overview

Osaka Gas jointly developed a highly efficient cost-effective recuperative burner with Chugai Ro Co., Ltd. for industrial furnaces used in the relatively low furnace temperature range of 1,000℃ or less. Since Chugai Ro has already developed a large-sized high performance recuperative burner, this burner is added to the line of its burners to support medium- and small-sized heat treatment furnaces.

Structure and Features

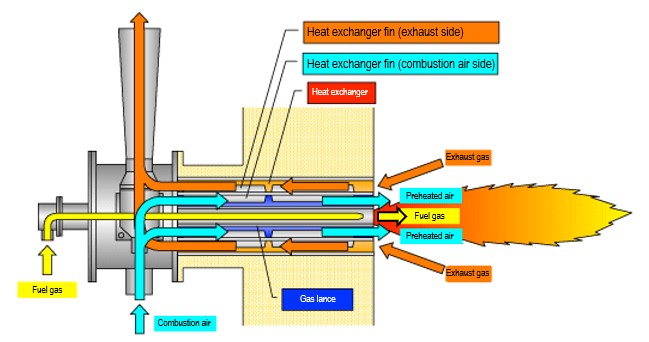

● Structure

At the heat exchanger, combustion air supplied to the burner is heat-exchanged with the exhaust gas taken from the furnace to become preheated hot air. The preheated air ejected from an air nozzle at a high speed is mixed with fuel gas in the furnace to foam flames, while the exhaust gas taken from the furnace with the ejector is heat-exchanged at the heat exchanger before being discharged.

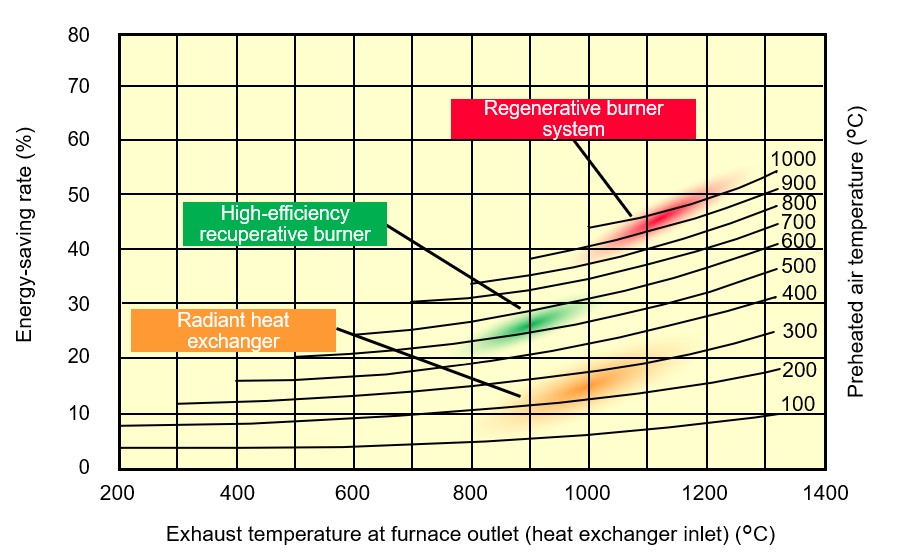

● High efficiency

The heat exchanger is contained in the burner body inserted in the furnace wall. With this structure, when the furnace temperature is 1,000℃, preheated air of at least 500℃ can be realized, bringing about a great energy-saving effect compared to burners using room temperature combustion air.

● Compact

The heat exchanger is integrated with the burner inserted in the furnace wall and does not require a large space around the burner. A simulation technique developed by Osaka Gas was used to minimize the exhaust gas pressure loss while maintaining sufficient heat exchange capacity. The result is an optimal shape and size of the heat exchanger fins.

● High-speed flame

Preheated air is ejected at high speeds from the air nozzle in the distal end of the heat exchanger. This design provides a great furnace gas agitation effect and achieve a better temperature distribution.

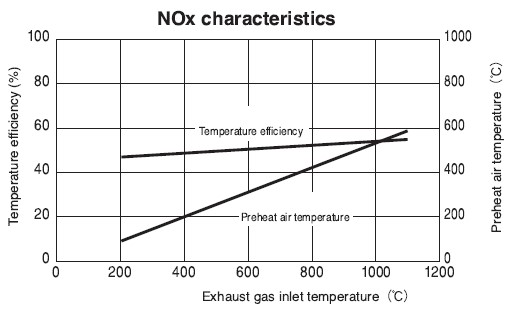

● Low NOx

The preheated air is ejected at highly speed, and the gas nozzle and air nozzle are separated appropriately. The structure makes slow combustion because the gas and the preheated air are mixed with the exhaust gas before burning. As a result, despite the burner using the preheated air, the flame temperature can be lowered and NOx emissions can be reduced.

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group