Industrial furnaces, burners

Gas Burner for Regenerative Glass Tank Furnaces

Introduction

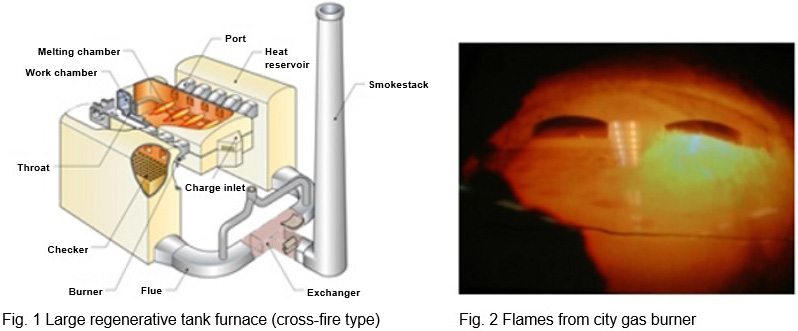

Osaka Gas has developed a burner as an alternative to heavy oil-firing burners for regenerative glass tank furnaces used in large-scale glass melting plants that melt more than tens of tons of glass per day. In a glass tank furnace, the temperature distribution inside the furnace is important for raw materials to undergo vitrification, melting, and removal of bubbles from the molten glass and be high-quality glass. To meet customers’ specific needs for temperature distribution in the furnace, burners Osaka Gas builds are all made-to-order ones. The company has converted more than 30 units (as of March 2020) and also had success in using gas for a large regenerative glass tank furnace with a melting capacity of more than 400 tons.

Efforts of Osaka Gas

■ Features of burners developed by Osaka Gas

- 1. To achieve highly luminous flames, high efficiency, and low NOx, we build made-to-order burners.

- 2. Our burners create flame shapes at will to produce an optimal oxidation/reduction atmosphere.

- 3. Flame shapes controlled in a versatile manner are intended to achieve an optimal temperature distribution and to improve product quality.

Burner Specifications

■ Features of conversion services provided by Osaka Gas

- 1. Osaka Gas designs all the gas burners available from it and builds them as made-to-order ones to construct the most suitable combustion system.

- 2. Osaka Gas will safely and responsibly carry out conversion to city gas and make adjustments.

- 3. Osaka Gas will also provide after-sales follow-up and energy-saving arrangements after conversion to city gas.

| Combustion type | Underport | Throughport |

|---|---|---|

| Photographed burner |  |

|

| Rated capacity | 700〜3,500kW | 700〜12,000kW |

| Gas type | 13A city gas | ← |

| Burner tip diameter | 50~80A | 100A |

| Purge air volume | 20〜30m3/h | Not applicable |

| Burner holder | Air-cooled or water-cooled | Water-cooled |

Table 1. Osaka Gas burner specifications

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group