Industrial furnaces, burners

Regenerative Burner System

Overview

A regenerative burner system is a combustion heating system that can recover waste heat with extremely high efficiency in industrial furnaces. Because of its high fuel consumption reduction effect, the system has been widely used as a last resort for cost saving, energy saving, and CO2 emission reduction, especially in relatively high temperature furnaces such as rolling furnaces, forging furnaces, heat treatment furnaces, melting furnaces, baking furnaces, deodorizing furnaces, and others.

Principle and Performance of Regenerative Burner System

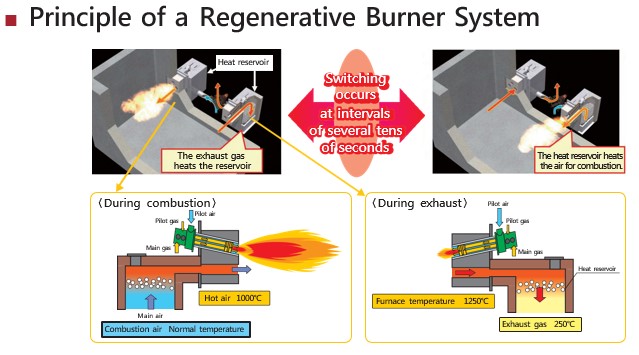

The regenerative burner system normally has a pair of burners integrated with heat storage tank, and the burners produce flames alternately at intervals of several tens of seconds. While one burner is burning, the exhaust gas passes through and heats the other burner’s heat storage medium in the heat storage tank to recover the energy of the exhaust gas. Then, when the other burner burns, the combustion air is preheated when it passes through the heat storage tank to recover the exhaust gas energy, which had conventionally been wasted, to ensure highly efficient combustion.

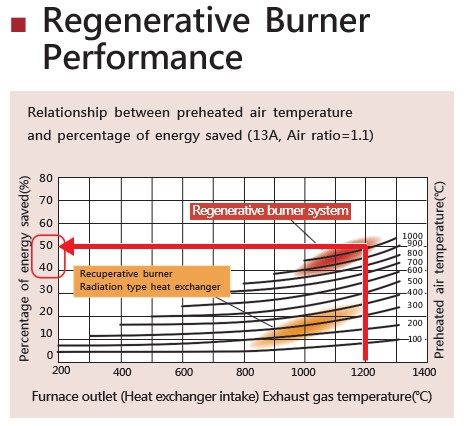

As shown above, for example, 1,200℃ exhaust gas energy can make generate about 1,000℃ preheated air, so almost 50% of energy saving can be achieved (compared to systems without exhaust gas energy recovery).

Features of Regenerative Burner System

- 1. Energy and cost savings

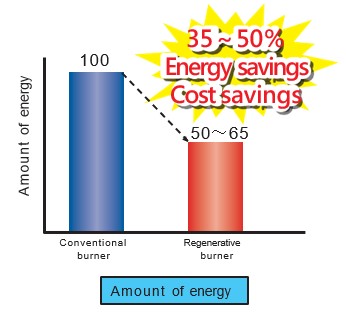

In general, 35%–50% of energy can be saved by introducing the regenerative burner system, though depending on the furnace temperature, air-fuel ratio, and operating patterns of the unit to be equipped with the burner.

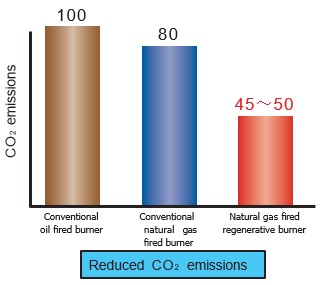

- 2. CO2 emission reduction

The considerable reduction in fuel consumption in turn enables a great reduction in CO2 emissions. Additional CO2 emission reduction can be achieved by changing the burner fuel from oil to natural gas due to lower CO2 emissions per unit heat value of natural gas.

- 3. Reduction of NOx emissions

Regenerative burners available from Osaka Gas, all of which are of a low NOx emission type, reduce total NOx emissions in conjunction with a reduced amount of exhaust gas attributed to their energy-saving capability.

- 4. Uniformity of furnace temperature distribution

The regenerative burner system ensures a uniform distribution of furnace temperature owing to the luminous flame effect brought about by high-temperature preheated air combustion and the furnace air agitation effect by alternating combustion, thereby providing benefits such as improved product quality and time and energy savings.

Regenerative Burners from Osaka Gas

- 1. Features

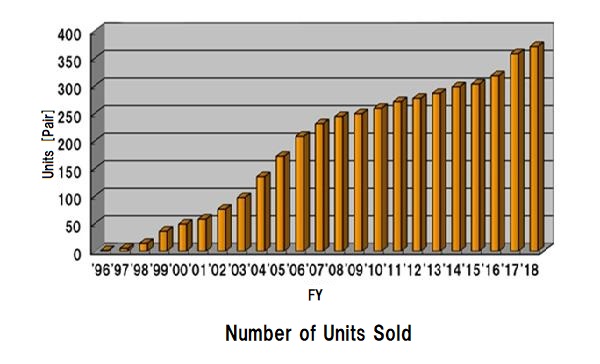

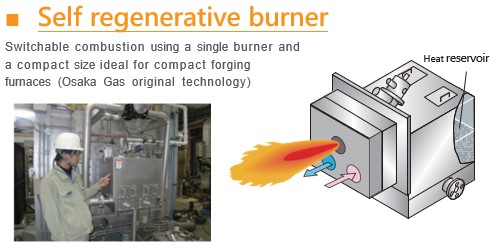

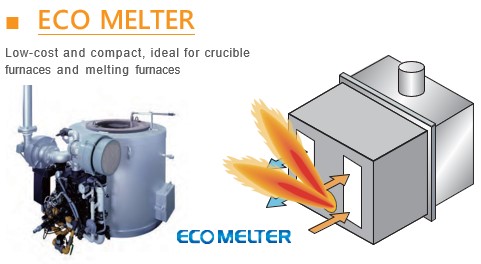

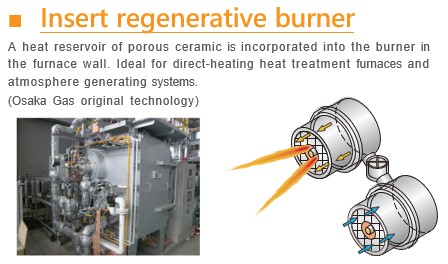

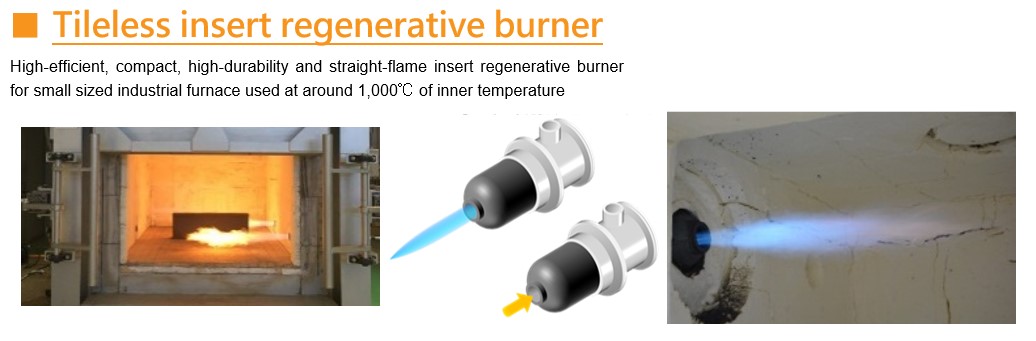

The regenerative burner system has mainly been introduced to rolling furnaces and other large-scale plants because its initial cost was high due to its complex structure compared to a typical burner. However, regenerative burners from Osaka Gas were developed for installation in small and medium-sized factories, and were designed to be compact and low-cost by the company’s proprietary technology development.

- 2. Product models

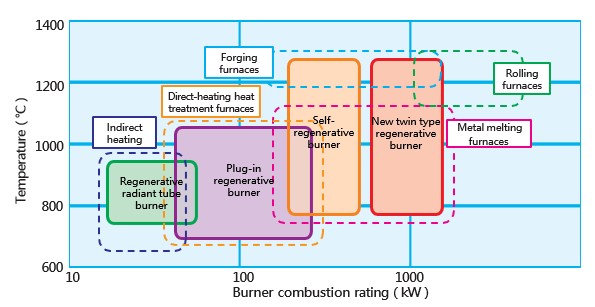

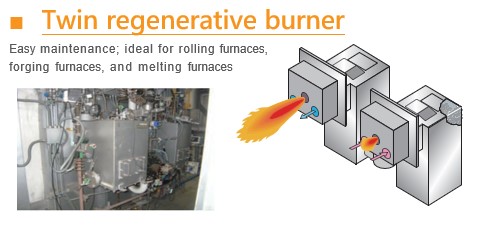

Osaka Gas has regenerative burners of various types and capacities to offer for a wide variety of applications.

- 3. Safety

The regenerative burners provided by Osaka Gas comply with “The index of safety technology of industrial gas combustion equipment” (Japan Gas Association) so as to be used more safely.

Regenerative burners are employed in large to small facilities for various purposes, such as bogie hearth furnaces, rotary furnaces, atmosphere gas generators, reverberatory melting furnaces, pipe muffle furnaces, ladle preheaters, and rotary retort furnaces, in addition to the above-mentioned equipment.

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group