Materials development

Poly(lactic acid)-based Resins for Films Capable of Inflation Molding

Overview

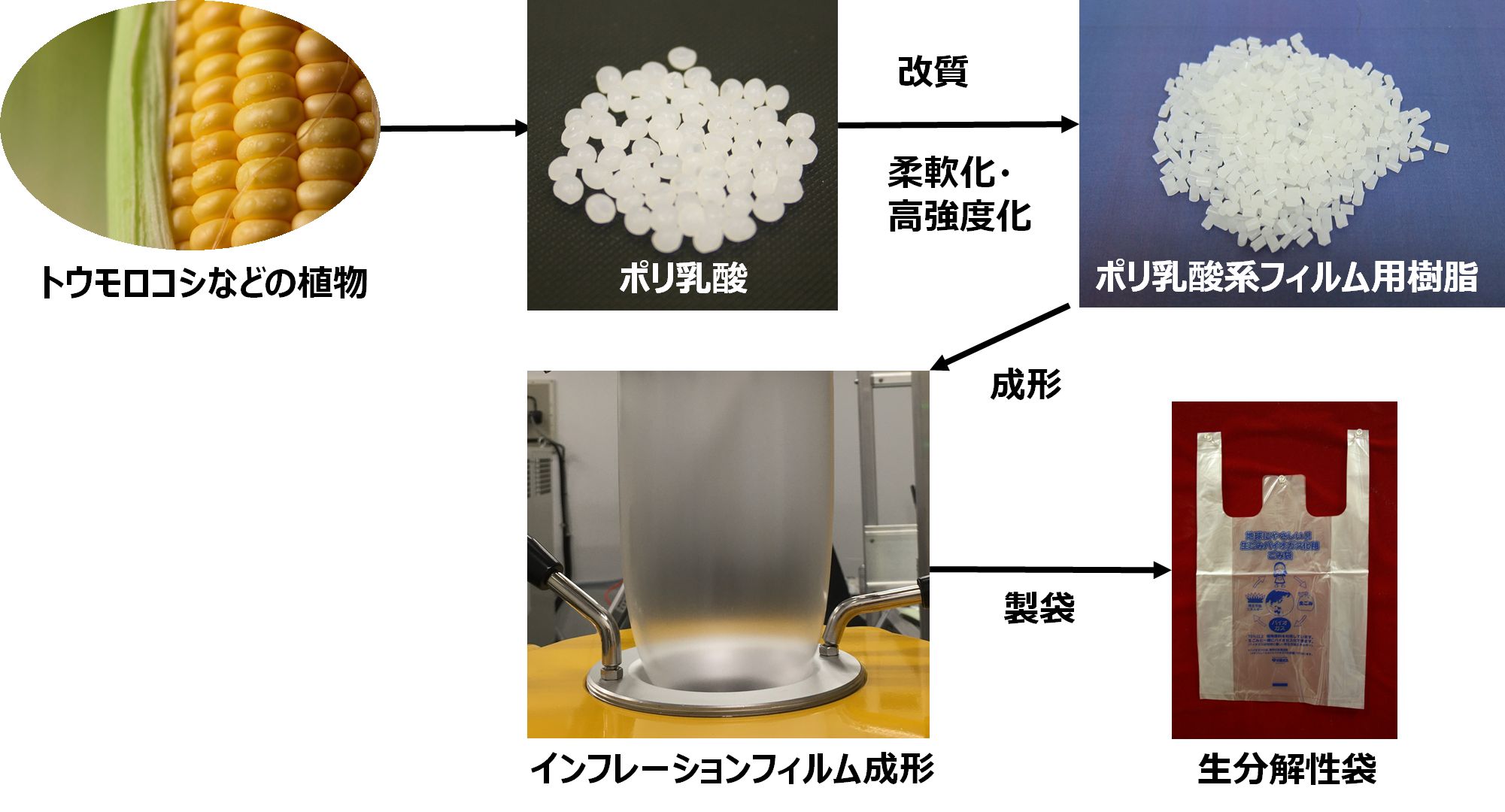

The Daigas Group has developed a new recycled resin material by compositing polyethylene gas pipe waste and PET bottle waste. By applying this technology to modify polylactic acid, which is attracting attention as a biomass (plant)-derived material, we have succeeded in producing garbage bags that could not be molded using polylactic acid alone.

This technology enables polylactic acid to be used to produce biodegradable agricultural mulch films, compost bags, and the like. In the future, it will also be possible for polylactic films to replace ordinary polyethylene ones and convert used bags into biogas without burning them.

Background

In recent years, polylactic acid—a biomass-derived resin—has been attracting attention as a low carbonization material; however, it had problems associated with its hard brittleness and inextensible quality.

In particular, for inflation film forming for trash bags, the use of polylactic acid alone was extremely difficult due to its low viscosity when melted.

Development and Features of Poly(lactic acid)-based Resins

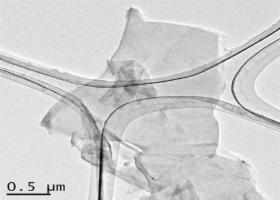

We modified the hard and brittle polylactic acid by applying the resin modification technology that we had developed, such as by compatibilization of PET-polyethylene blends, and created a resin that can be used for inflation film forming.

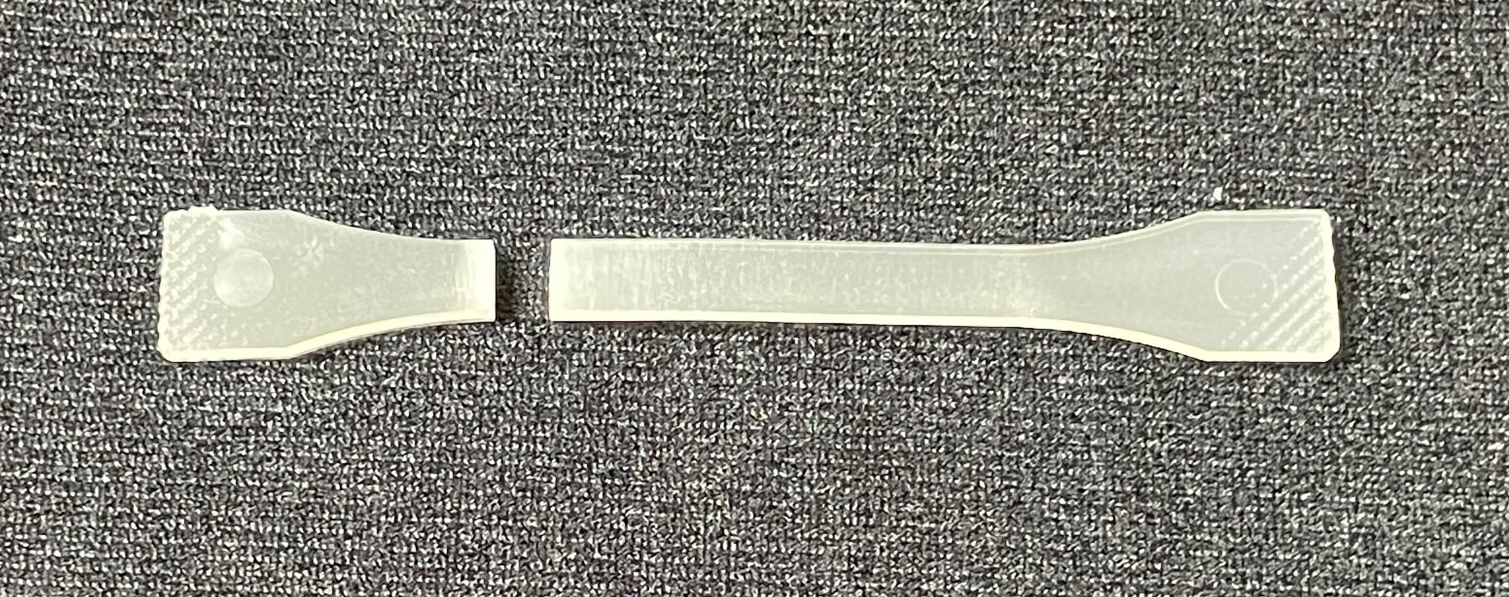

This resin can be used with general-purpose inflation film forming machines and can be used to manufacture a flexible and high-strength film while maintaining a high degree of biomass and biodegradability.

In addition, compared to other biodegradable resins, it is stable at room temperature and can be stored for a long time. Accordingly, it is expected to reduce film production cost.

Fig. 3. Modification of polylactic acid

Fig. 4. Properties of modified polylactic acid (injection molding)

Fig. 5. Inflation film forming using modified polylactic acid

Applications of Biodegradable Films Made from This Resin

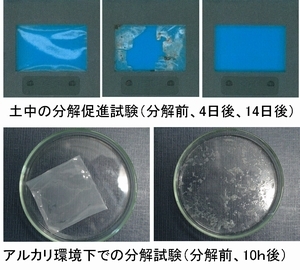

In terms of use for biodegradable agricultural mulch films and compost bags, biodegradable films made from this resin are characterized by high strength and both preservability and degradability.

The films have good storage stability under normal indoor conditions for a certain reasonable period of time, so they can be expected to replace general polyethylene films (plastic grocery bags, trash bags, food packaging, etc.) in the future.

Moreover, using the biogasification technology developed by Osaka Gas, it is possible to decompose them in a short time and ultimately convert them to biogas. As a result, kitchen waste can be thrown in for gasification together with trash bags, increasing the amount of biogas. In addition, it eliminates the need to separate and dispose of trash bags, enabling labor savings.

Fig. 6. Biodegradable bag

Fig. 7. Decomposition test

Future Plans

We will develop applications for biodegradable films, making the most of the above characteristics, develop decomposition control technology, and aim to achieve a biomass content approaching 100% and create a more environmentally friendly material.

Meanwhile, using this polylactic acid modification technology, we are working on development of 100% biomass materials that are hard and highly heat-resistant, contrary to films.

In this way, we will help build a low-carbon society by deploying the material to applications in which polylactic acid could not be used in the past due to its low levels of heat resistance, impact resistance, and tensile elongation.

Related contents

TAG SEARCH

- Evolving residential gas appliances

- Evolving residential gas appliances Water heaters, space heaters, dryers Cooking appliances Smart Equipment Fuel Cell systems

- Evolving commercial and industrial gas appliances

- Evolving commercial and industrial gas appliances Cogeneration (CHP) units Air conditioning systems, kitchen appliances Bio, water treatment Industrial furnaces, burners Energy management, IoT

- Enhancing the safety and economic efficiency of LNG regasification

- Enhancing the safety and economic efficiency of LNG regasification Utilization of cold energy Plant materials Power generation technology

- Developing next-generation businesses through enterprising initiatives

- Developing next-generation businesses through enterprising initiatives Materials development Measurement Simulation, data analysis Food science Material evaluation

- Contributing to conserving the environment and achieving a carbon neutral society

- Contributing to conserving the environment and achieving a carbon neutral society Methanation Hydrogen, ammonia Biogas Energy management Renewable Energy

- Technologies of Group companies

- KRI, Inc. Osaka Gas Chemicals Group OGIS-RI Group